An Ounce of Prevention

Can inherently safer technology save us from chemical accidents and terrorists?

As Benjamin Franklin famously said, “an ounce of prevention is worth a pound of cure.” Franklin’s comment, originally made in reference to home fire safety, is characteristically timeless. Today, many are looking to the principle of prevention as a way to reduce the incidence and severity of chemical plant disasters.

The threat of chemical disaster is present and severe. Thousands of chemical plants endanger millions of American workers and community members—according to the Congressional Research Service, over 2,500 hazardous chemical facilities subject to EPA risk management requirements each threaten over 10,000 people in the event of a worst-case scenario release, with about 90 threatening over one million people. High profile disasters like the 2013 West, Texas fire and explosion that killed 15 people, or the 2012 fire at a Chevron refinery in Richmond, California that sent 15,000 people in the surrounding community to the hospital, as well as smaller daily incidents and looming terrorist threats, have led to calls for improved measures to improve safety and security regulations.

Among the suggestions raised is the use of “inherently safer technology” (“IST”), a strategy for risk management that focuses on eliminating or reducing hazardous substances and processes within an operation, rather than creating responsive systems to mitigate the risks of these hazards. In the simplest formulation of one principle of inherent safety, from Trevor Kletz, the chemical safety guru who coined the concept, “what you don’t have, can’t leak.” Common examples of IST strategies include reducing the quantity of dangerous substances stored or used at a facility, or replacing these substances with less toxic, reactive, flammable, or explosive alternatives. In a popular IST success story, many water treatment facilities have replaced highly toxic chlorine gas with liquid bleach, which does not pose the same threats of accidental or criminal release.

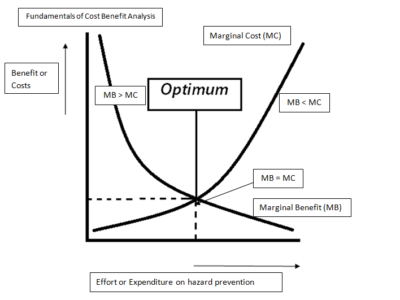

The benefits of IST are largely self-evident. When a hazard is reduced or removed, fewer additional safety protections are required to protect workers or the public, resulting in long-term cost savings or lower overall risk. As they say, an ounce of prevention….

Of course, the details are more complicated. Detractors cite concerns over the costs of conducting IST reviews, or the difficulties posed in implementing IST. What if, in removing a hazard, we introduce other—perhaps unknown—hazards? And how should we compare unlike hazards, when we have to choose? Both those in favor of IST regulations and those against agree that IST is at best only part of the solution to chemical process hazards, to be used in conjunction with other strategies.

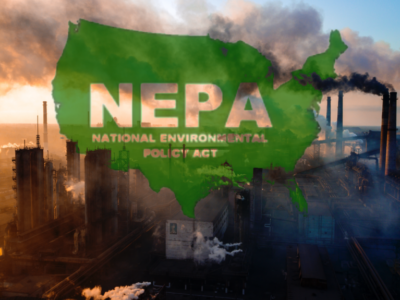

Debate on the merits of IST has increased recently, as the possibility of revised federal regulations comes into view. Last August, prompted by the West, Texas disaster and other tragedies, President Obama signed Executive Order 13650, establishing a task force to rethink America’s response to chemical facility safety and security threats. The task force consists of representatives from EPA, OSHA, the Department of Homeland Security, the Department of Justice, the Department of Agriculture, and the Department of Transportation. Under the Order, these agencies are tasked with improving measures to reduce the risks of both normal accidents and terrorist attack. Among the topics in which the task force has indicated an interest is the possibility of incorporating IST into existing process safety programs. (These programs, like EPA’s Risk Management Program, OSHA’s Process Safety Management program, and DHS’ Chemical Facility Anti-Terrorism Standards, have historically encouraged responsive risk management strategies more akin to cure than prevention.)

Last Friday, the task force held a stakeholder listening session at UCLA, the latest in a tour of similar sessions across the country. Many of those who spoke at this session called on the task force to require facilities to implement IST and other preventative safety measures. Two faculty members from UCLA Law (full disclosure: I was one, along with Professor Tim Malloy) spoke on the idea of adding IST regulations, and described a UCLA policy brief on inherent safety regulation, planned for release this spring. Members of the task force, particularly EPA Assistant Administrator Mathy Stanislaus, showed interest through a number of questions on how they might include IST in their EO 13650 actions.

Although the idea of IST dates back to the 1970s, it has yet to be put to use as a required component of chemical process safety. While IST is now required in New Jersey and California’s Contra Costa County, these laws provide significant wiggle room. A number of federal IST bills have died in Congress.

This may be about to change, however. Both the President and Vice President were vocal advocates of IST and preventative safety measures during their days in Congress, and the Executive Order indicates a strong push within the administration to overhaul the current regulatory system. There has also been a recent push within California for statewide IST requirements.

As IST gathers support, many of the traditional objections to the concept are being shown to lack merit. For example, concerns about cost may be parried by requiring only economically and otherwise feasible changes be implemented, as in the New Jersey and Contra Costa County laws, and aborted federal bills. Problems of risk tradeoffs and “unlike hazards” are largely red herrings: tradeoffs are explicitly accounted for in standard IST methodologies, and applying principles of alternatives analysis can allow reasonable comparison between hazards. (Since any decision making requires a weighing of hazards, it is more an advantage than a fault of IST review that it makes explicit the preferences underlying these choices.)

The task force is expected to complete the final requirements of Executive Order 13650 in May, including release of a “plan for implementing practical and effective improvements to chemical risk management.” Prevention, cure, or something else entirely? Stay tuned.

Reader Comments